Understanding XLPE Wires: Advantages, Applications, and Durability

Fast-paced industrial and residential world, the demand for reliable electrical wiring has never been higher. Among the various types of electrical cables, XLPE Wire has emerged as a preferred choice for both commercial and domestic applications. But what makes XLPE wires stand out from traditional wiring solutions? This article delves deep into the world of XLPE wires, exploring their advantages, applications, and durability, providing a comprehensive guide for anyone looking to understand this essential electrical component.

What is XLPE Wire?

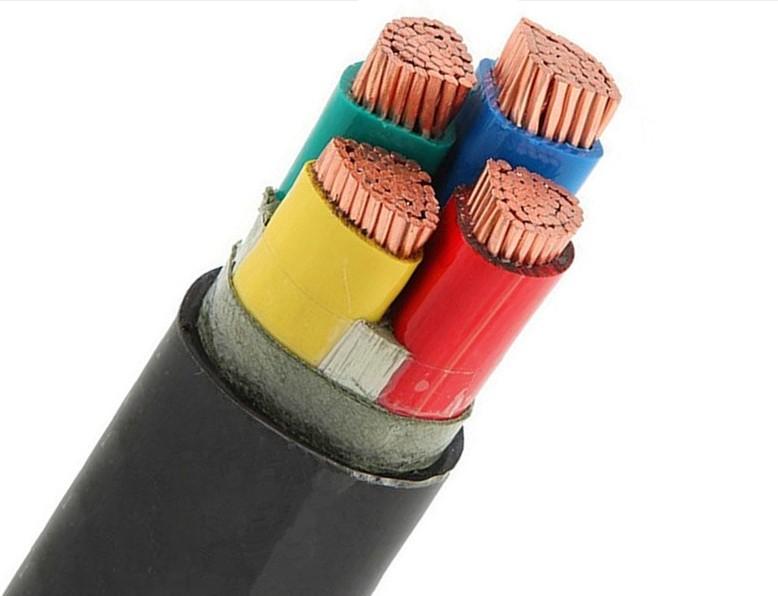

XLPE stands for Cross-Linked Polyethylene, a type of insulation used in electrical cables to enhance their performance. Unlike conventional PVC-insulated wires, XLPE wires undergo a chemical process that “cross-links” the polyethylene molecules. This cross-linking process significantly improves the thermal, mechanical, and chemical properties of the insulation.

In simple terms, XLPE wires are designed to withstand higher temperatures, resist chemical attacks, and maintain performance even under challenging environmental conditions. This makes them ideal for applications where reliability and safety are critical.

Key Advantages of XLPE Wire

The adoption of XLPE wires has increased across industries due to several compelling advantages:

1. High Thermal Resistance

One of the most significant advantages of XLPE wires is their ability to handle high temperatures. While traditional PVC wires can typically operate safely up to 70°C, XLPE wires can withstand continuous temperatures of up to 90°C and short-circuit temperatures as high as 250°C. This thermal tolerance reduces the risk of insulation failure and makes XLPE wires ideal for high-load applications.

2. Enhanced Mechanical Strength

XLPE insulation provides excellent mechanical strength. It is resistant to abrasion, cutting, and impact, which makes it suitable for environments where cables are exposed to mechanical stress. This robust construction ensures a longer lifespan, even in challenging industrial settings.

3. Chemical and Corrosion Resistance

Industrial environments often expose wires to chemicals, oils, and other corrosive agents. XLPE wires are highly resistant to these substances, ensuring that the insulation remains intact over time. This chemical resistance minimizes maintenance costs and enhances safety in chemical plants, refineries, and other industrial facilities.

4. Low Dielectric Loss

XLPE wires exhibit low dielectric loss, meaning they transmit electricity efficiently with minimal energy loss. This characteristic makes them ideal for long-distance power transmission and high-voltage applications, where energy efficiency is critical.

5. Non-Hygroscopic Nature

Unlike some insulating materials, XLPE does not absorb moisture. This property ensures consistent electrical performance even in humid or wet environments. It also reduces the risk of short circuits and electrical failures, making XLPE wires suitable for outdoor and underground installations.

6. Fire Retardant Properties

XLPE wires are designed to be self-extinguishing, meaning they do not propagate flames in case of fire. This fire-retardant characteristic enhances safety in residential, commercial, and industrial settings, helping prevent fire-related accidents and property damage.

Applications of XLPE Wire

Thanks to its robust properties, XLPE wires are used across a wide range of applications. Here are some of the most common areas where XLPE wires are deployed:

1. Residential Wiring

In homes, safety and durability are paramount. XLPE wires are used in residential buildings for internal wiring, providing reliable insulation that can handle high current loads without overheating. Their fire-retardant properties also make them a safer choice for domestic environments.

2. Industrial Installations

Industries require wiring solutions that can endure harsh conditions, including chemical exposure, high temperatures, and mechanical wear. XLPE wires are commonly used in manufacturing plants, refineries, and other industrial facilities due to their strength, thermal resistance, and chemical stability.

3. Power Transmission and Distribution

High-voltage XLPE wires are widely used in power transmission and distribution networks. Their low dielectric loss and high thermal resistance make them suitable for long-distance electricity transport, ensuring minimal energy loss and reliable operation.

4. Underground and Outdoor Installations

XLPE wires are ideal for underground and outdoor applications due to their resistance to moisture, UV radiation, and environmental stress. These wires can endure exposure to sunlight, rain, and soil chemicals without compromising performance, making them perfect for cable laying in open spaces or underground tunnels.

5. Automotive and Transportation

In automotive and transportation sectors, XLPE wires are used in vehicles, trains, and aircraft for critical electrical systems. Their ability to withstand vibrations, temperature fluctuations, and mechanical stress ensures consistent performance in demanding mobile applications.

Durability of XLPE Wire

Durability is a critical factor when selecting electrical wiring, and XLPE wires excel in this regard. Their durability stems from several intrinsic properties:

1. Thermal Stability

XLPE wires maintain their insulation integrity under both low and high temperatures. This thermal stability prevents insulation breakdown, extending the life of the wire and reducing the risk of electrical failures.

2. Mechanical Robustness

The cross-linked structure provides excellent mechanical strength, making XLPE wires resistant to cuts, abrasion, and deformation. This ensures that even in physically demanding environments, the wires remain functional and safe.

3. Chemical Resistance

Exposure to chemicals and oils can degrade many types of insulation. XLPE wires, however, resist chemical corrosion, ensuring consistent performance and reducing maintenance needs.

4. Environmental Resilience

Whether buried underground, exposed to sunlight, or installed in damp conditions, XLPE wires remain durable. Their non-hygroscopic and UV-resistant properties make them ideal for a variety of environmental conditions.

5. Long Lifespan

Thanks to their combined resistance to thermal, mechanical, and chemical stresses, XLPE wires can last several decades without significant deterioration. This longevity translates to fewer replacements, lower maintenance costs, and enhanced overall safety.

Choosing the Right XLPE Wire

When selecting XLPE wires for a project, several factors should be considered:

-

Voltage Rating – Ensure the wire can handle the voltage requirements of your application. XLPE wires are available for low, medium, and high-voltage use.

-

Current Capacity – Choose a wire gauge suitable for the expected current load to prevent overheating.

-

Environmental Conditions – Consider exposure to moisture, chemicals, sunlight, or mechanical stress when selecting the wire.

-

Compliance and Standards – Ensure the XLPE wire meets industry standards and certifications for safety and performance.

-

Installation Requirements – Some applications may require flexible or rigid wires, so consider the ease of installation.

Conclusion

In summary, XLPE Wire is a highly versatile and durable electrical solution suitable for a wide range of applications. Its superior thermal resistance, mechanical strength, chemical resistance, and fire-retardant properties make it a reliable choice for residential, commercial, industrial, and outdoor installations. By understanding the advantages, applications, and durability of XLPE wires, engineers, electricians, and homeowners can make informed decisions that ensure safety, efficiency, and long-term performance.

Investing in quality XLPE wiring is not just about meeting immediate electrical needs—it is about ensuring a robust, safe, and future-proof electrical infrastructure. Whether you are upgrading your home’s electrical system, wiring an industrial facility, or managing power distribution, XLPE wires offer unmatched reliability and peace of mind.