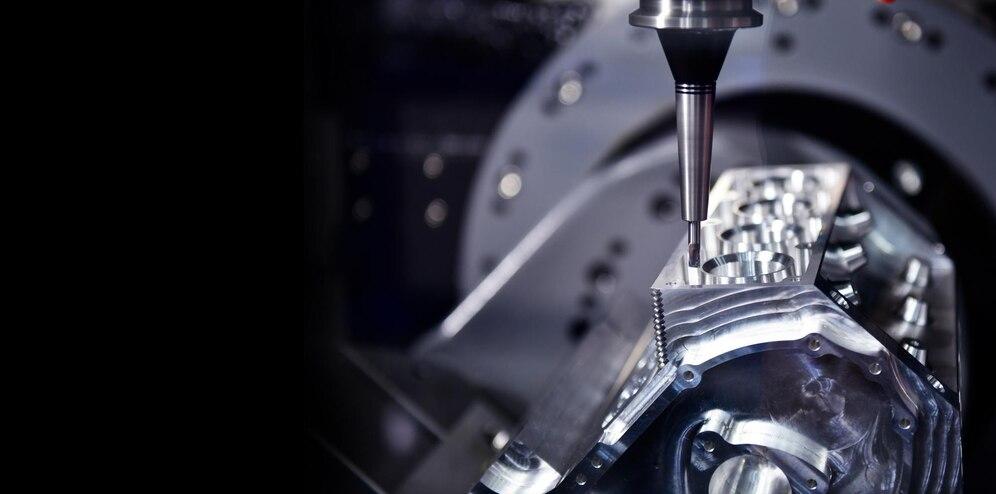

In the world of advanced manufacturing, Five-Axis Machining has set new standards for precision, flexibility, and complexity in creating intricate components. As industries continue to demand more complex geometries and tighter tolerances, five-axis CNC machines have become indispensable tools for a wide range of applications, from aerospace to medical devices. In this blog, we will explore the revolutionary capabilities of five-axis machining, its key benefits, and why it’s a game-changer in modern manufacturing.

What is Five-Axis Machining?

Five-axis machining refers to a type of CNC (Computer Numerical Control) machining that uses five separate axes of movement to precisely shape and cut a workpiece. Unlike traditional three-axis machines, which only allow the cutting tool to move along the X, Y, and Z axes (left-right, up-down, and depth), five-axis machines add two additional axes, often referred to as A and B (rotational axes), allowing for full 3D shaping and milling of the workpiece.

This additional flexibility makes five-axis machining perfect for creating complex parts that require multi-directional cutting, reducing the need for multiple setups and improving overall accuracy. The machine's ability to manipulate the cutting tool from any angle makes it possible to machine intricate features on a workpiece in a single setup, increasing both speed and precision.

How Does Five-Axis Machining Work?

Five-axis machining operates by moving the workpiece along five axes simultaneously. Here’s a breakdown of how the axes function:

-

X, Y, Z Axes: These are the traditional three axes of a CNC machine, representing horizontal movement (X), vertical movement (Y), and depth (Z). These axes control the linear motion of the cutting tool.

-

A and B Axes: The A and B axes introduce rotational movement to the machine. The A-axis rotates the workpiece around the X-axis, while the B-axis rotates around the Y-axis. These axes enable the cutting tool to access virtually any part of the workpiece, regardless of the angle.

This multi-axis approach enables the machining of parts with complex geometries, such as turbine blades, complex molds, and components with intricate features, all in a single setup. The precise coordination of all five axes results in highly accurate and finely detailed parts.

Key Advantages of Five-Axis Machining

1. Improved Precision and Accuracy

One of the primary benefits of five-axis machining is its ability to achieve incredibly high precision. The five-axis system ensures that the cutting tool is always in the ideal position, reducing human error and producing parts with tight tolerances. This makes five-axis machining an essential tool for industries such as aerospace, automotive, and medical, where precision is paramount.

2. Reduced Setup Time

Traditional machining often requires multiple setups to machine different sides of a workpiece, increasing both labor time and the potential for errors. With five-axis machining, the ability to perform multi-directional cutting in a single setup not only reduces the number of setups required but also significantly shortens production cycles. This results in faster lead times and increased productivity.

3. Enhanced Flexibility

Five-axis machining provides incredible flexibility in terms of part geometry. It allows manufacturers to create complex 3D geometries that would be difficult or impossible to achieve with a traditional three-axis machine. From turbine blades and engine components to custom medical implants, five-axis machines are capable of handling a wide range of complex parts.

4. Higher Quality Parts

The precise and continuous motion of the cutting tool during five-axis machining results in smoother surfaces and reduced tool wear. This, combined with the machine's ability to access hard-to-reach areas, results in higher quality parts that meet exacting industry standards. The reduced need for secondary operations also ensures that the parts maintain their intended functionality and finish.

5. Optimized Tool Paths

In five-axis machining, the cutting tool can approach the material from virtually any angle, optimizing the tool paths for maximum efficiency. This not only improves the quality of the cut but also extends the life of the cutting tools by reducing excessive wear. Furthermore, optimized tool paths contribute to reducing the overall cycle time of the machining process.

Applications of Five-Axis Machining

The ability to create complex, high-precision parts with minimal setups has made five-axis machining essential across many industries. Some key applications include:

1. Aerospace Industry

The aerospace sector relies heavily on five-axis machining for the production of intricate parts, such as turbine blades, engine components, and structural components. These parts require high precision and tight tolerances to ensure optimal performance. Five-axis machines enable manufacturers to produce these components efficiently and with the accuracy needed for the demanding aerospace standards.

2. Automotive Manufacturing

Five-axis machining is widely used in the automotive industry for producing complex parts like transmission components, engine blocks, and moldings. The flexibility of five-axis machines allows manufacturers to create detailed features and ensure the quality and durability of automotive parts. Additionally, the ability to machine multiple surfaces in one setup reduces costs and improves productivity.

3. Medical Devices

In the medical device industry, precision is a critical requirement. Five-axis machines are used to produce complex, highly accurate medical components such as implants, surgical tools, and prosthetics. These parts often have intricate geometries, making five-axis machining an ideal solution for creating custom, patient-specific devices with a high level of accuracy.

4. Tool and Die Making

In tool and die making, five-axis machining plays a crucial role in the production of complex molds and dies. The ability to create detailed features with tight tolerances ensures that molds can produce high-quality, precise products. This capability is particularly important for industries such as injection molding, where the quality of the mold directly impacts the final product.

5. Energy Sector

The energy sector, particularly in renewable energy, benefits from five-axis machining when producing components like wind turbine blades and components for power generation systems. These parts often require complex shapes that are not easily produced with traditional machining methods, making five-axis machines an essential tool for efficient and precise production.

Challenges of Five-Axis Machining

While five-axis machining offers numerous benefits, it does come with some challenges:

-

High Initial Investment: The cost of a five-axis CNC machine can be significantly higher than traditional three-axis machines. This can be a barrier for smaller manufacturers looking to adopt this technology.

-

Complex Programming: Programming a five-axis machine requires specialized knowledge and expertise. The complexity of the tool paths and movements can make programming more challenging than with traditional machines.

-

Maintenance and Calibration: Maintaining a five-axis machine requires regular calibration and servicing to ensure it operates at peak performance. Regular maintenance is essential to avoid costly downtime.

Why Choose Five-Axis Machining?

Choosing five-axis machining means choosing efficiency, precision, and flexibility. This technology is ideal for industries that require complex components with intricate geometries, tight tolerances, and high-quality finishes. Although the initial investment and programming may be more challenging, the benefits of faster production, reduced setup times, and higher-quality parts make five-axis machining a worthwhile investment for any manufacturer looking to stay competitive.

Conclusion

Five-axis machining is a game-changer in the world of manufacturing. With its ability to produce highly complex, precise, and high-quality parts with fewer setups, it offers unmatched flexibility for industries ranging from aerospace to medical device manufacturing. Despite the higher costs and more complex programming, the benefits of five-axis machining far outweigh the challenges, making it an essential tool for modern manufacturing.

Embrace the future of manufacturing with five-axis machining, and unlock a world of precision, speed, and innovation for your business. Whether you are creating aerospace components, custom medical implants, or intricate automotive parts, five-axis machines provide the accuracy and efficiency required to meet the demands of today’s advanced industries.