In 2025, over 30 billion IoT devices are projected to be in use globally, many of them operating in harsh environments or compact enclosures. According to Statista, the global IoT market is expected to exceed $1.6 trillion by 2025, with a significant portion driven by industrial and edge applications that demand high-performance and reliable hardware. These trends make effective thermal management a crucial part of IoT hardware development.

High-performance IoT devices often involve powerful processors, edge AI chips, and wireless modules. These components generate significant heat. If not properly managed, heat can degrade performance, reduce lifespan, or cause device failure. This article explores essential thermal management techniques to ensure longevity, reliability, and optimal function of IoT hardware.

Why Thermal Management Matters in IoT Hardware Development

In IoT hardware development, thermal management affects:

-

System stability: High temperatures can cause unexpected shutdowns or slowdowns.

-

Component lifespan: Heat accelerates material degradation and solder joint failure.

-

Power efficiency: Devices waste more power when cooling is inefficient.

-

Data accuracy: Sensors may show inaccurate readings when exposed to heat.

Real-World Failure Example

In a factory automation project, a smart sensor embedded near a motor failed intermittently. Post-failure diagnostics showed thermal stress caused the main IC to detach from the PCB due to repeated thermal cycling. A simple passive heatsink and relocation fixed the issue.

Key Heat Sources in IoT Devices

Understanding what generates heat in IoT systems helps in selecting the right cooling technique:

| Component | Typical Temperature Rise |

| Microcontrollers (MCUs) | 20–50°C above ambient |

| Edge AI Chips | 30–80°C above ambient |

| RF Modules (Wi-Fi, LTE) | 15–40°C above ambient |

| Power Regulators | 20–60°C above ambient |

Passive Thermal Management Techniques

Passive solutions are reliable, cost-effective, and widely used in IoT hardware development.

1. Heatsinks

-

Absorb and dissipate heat into the air

-

Made from aluminum or copper

-

Often used with SoCs and voltage regulators

Example: A Raspberry Pi 4 runs 10–15°C cooler with a basic aluminum heatsink on its CPU.

2. Thermal Pads and Pastes

-

Fill air gaps between components and heatsinks

-

Improve thermal conductivit

-

Easy to apply and inexpensive

Use case: Applying thermal paste between a Wi-Fi module and its aluminum shield reduces RF interference caused by overheating.

3. Heat Spreaders

-

Distribute heat across a larger surface area

-

Can be metal or graphite-based

-

Useful in thin IoT devices like wearables

Example: Smartwatches use graphite heat spreaders to maintain comfort and prevent overheating.

4. Enclosure Design

-

Use vents or perforations to allow airflow

-

Choose thermally conductive enclosure materials like aluminum

-

Avoid placing heat-generating components near corners or in closed pockets

Active Thermal Management Techniques

Active techniques involve powered components that control or move heat away from sources.

1. Fans and Blowers

-

Force air across heatsinks or hot components

-

Ideal for gateways or industrial controllers

-

Consume power but significantly reduce temperatures

Caution: Not suitable for battery-powered or compact devices.

2. Thermoelectric Coolers (TECs)

-

Use Peltier modules to move heat using electric current

-

Offer precision cooling but consume more power

-

Often paired with heat sinks or fans

Example: A high-speed edge inference camera used a TEC to maintain consistent performance at 65°C ambient.

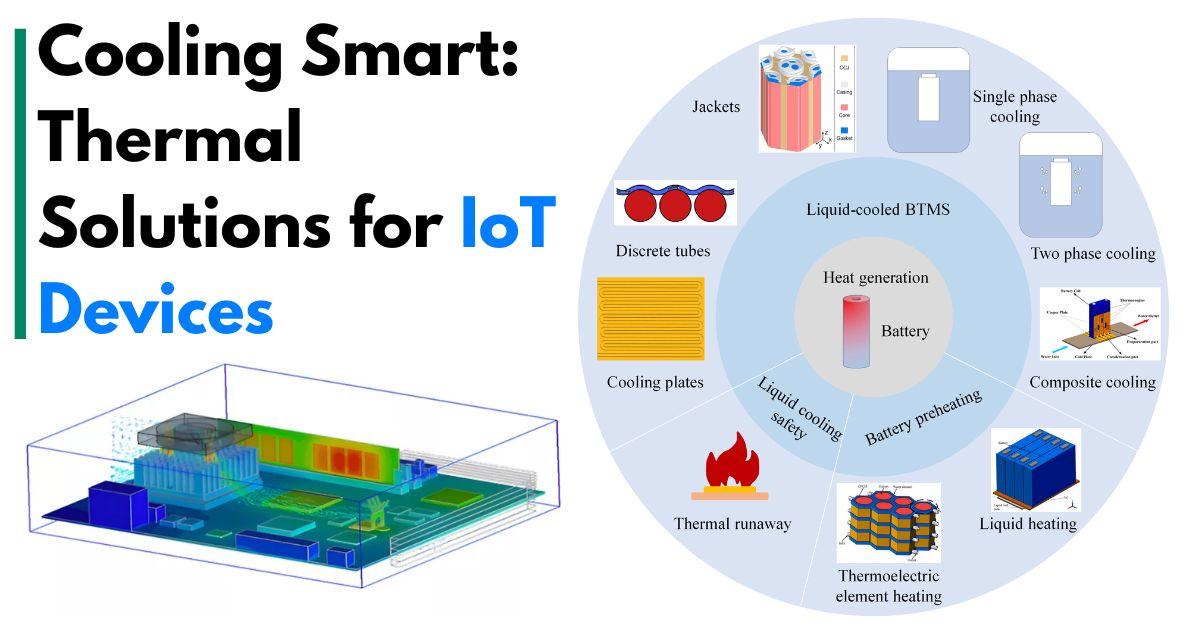

3. Liquid Cooling

-

Circulates coolant through tubes near hot components

-

Used in high-end industrial IoT servers or rugged edge devices

-

Complex and expensive, but extremely effective

Fact: Industrial-grade IoT servers with 16-core edge CPUs use custom liquid cooling loops for long-term reliability.

Thermal Simulation and Modeling

Before building a physical prototype, engineers use simulation tools to predict heat flow.

Tools Commonly Used:

-

ANSYS Icepak

-

COMSOL Multiphysics

-

SolidWorks Flow Simulation

These tools allow for:

-

Simulating airflow and temperature distribution

-

Predicting hot spots

-

Testing enclosure designs virtually

Tip: Early thermal simulation during IoT hardware development reduces redesign costs and time-to-market.

Software-Based Thermal Management

Firmware and software can actively manage heat by controlling device behavior.

1. Dynamic Frequency Scaling (DFS)

-

Reduces CPU frequency when idle or under low load

-

Lowers power and heat output

2. Thermal Throttling

-

Reduces performance when temperature crosses safe thresholds

-

Prevents damage but may degrade user experience

3. Sleep and Hibernate Modes

-

Switch off modules like Wi-Fi or BLE when not in use

-

Crucial for wearables and IoT sensors

Example: Smart thermostats throttle the processor when idle, reducing board temperature by up to 12°C.

Choosing the Right Technique Based on Use Case

| Device Type | Preferred Thermal Solutions |

| Wearables | Heat spreaders, low-power chips, sleep modes |

| Industrial Sensors | Heatsinks, airflow vents, thermal pads |

| Edge AI Devices | Active cooling, TECs, DFS, thermal throttling |

| Smart Home Gateways | Passive airflow, dynamic fan control |

| Agricultural IoT Nodes | Enclosure design, solar shielding, DFS |

IoT Hardware Development and Environmental Considerations

The environment in which an IoT device operates plays a major role in thermal planning.

High-Temperature Areas

-

Use industrial-grade components rated for 85–105°C

-

Avoid plastic enclosures that insulate heat

Cold Climates

-

Excessive cooling can cause condensation

-

Use conformal coatings to protect sensitive parts

Outdoor Installations

-

Apply UV and IR-resistant coatings

-

Use metallic enclosures that radiate heat effectively

Best Practices in Thermal Design

-

Simulate early and test often

-

Keep heat sources apart in PCB layout

-

Use copper planes to spread heat in PCB

-

Choose components with thermal data in datasheets

-

Always test under worst-case conditions (max load, ambient temp)

Real-World Case Study: Industrial IoT Gateway

A manufacturing client deployed edge AI gateways near high-speed conveyor belts. The initial design failed stress tests due to thermal shutdowns.

Initial Setup:

-

8-core ARM CPU

-

Wi-Fi, LTE, Zigbee modules

-

Plastic enclosure, no heatsinks

Issues:

-

92°C on CPU under load

-

75°C ambient inside enclosure

Solution:

-

Aluminum heatsink with fins

-

Internal airflow vents

-

Dynamic frequency scaling enabled

Outcome:

Peak CPU temp dropped to 65°C. Uptime improved by 37%, and no thermal failures were reported post-deployment.

Conclusion

Thermal management is a vital aspect of IoT hardware development, especially as device complexity and processing demands increase. Using the right mix of passive, active, and software-based techniques ensures high-performance devices stay safe, reliable, and efficient over time.

Understanding your thermal budget, component specs, and real-world conditions will help you create devices that not only function properly but thrive in their target environment. As IoT hardware development continues to evolve, so must the strategies we use to manage heat effectively.

Frequently Asked Questions (FAQs)

1. Why is thermal management critical in IoT hardware development?

It ensures device reliability, prevents overheating, and maintains performance in long-term deployments.

2. What’s the difference between passive and active thermal solutions?

Passive methods don’t use power (like heatsinks), while active methods (like fans or TECs) require power to operate.

3. Can software really help reduce hardware heat?

Yes, software techniques like frequency scaling, sleep modes, and throttling can manage power consumption and lower heat output.

4. What are some signs of poor thermal management in IoT devices?

Frequent restarts, sensor failures, performance drops, and burnt PCB traces are common indicators.

5. How early should thermal planning start in the development cycle?

Thermal considerations should begin at the PCB layout and enclosure design stage, not after testing begins.