I. Introduction: The Critical Need for Custom Heat Sink Technology

-

Catchy Hook: The relentless demand for smaller, faster, and more powerful electronic devices has made thermal management the single most critical challenge in modern engineering.

-

Defining the Core Problem: Standard, off-the-shelf heat sinks often fail to meet the stringent thermal and spatial requirements of high-performance applications (e.g., AI servers, 5G telecom, electric vehicles, industrial power electronics).

-

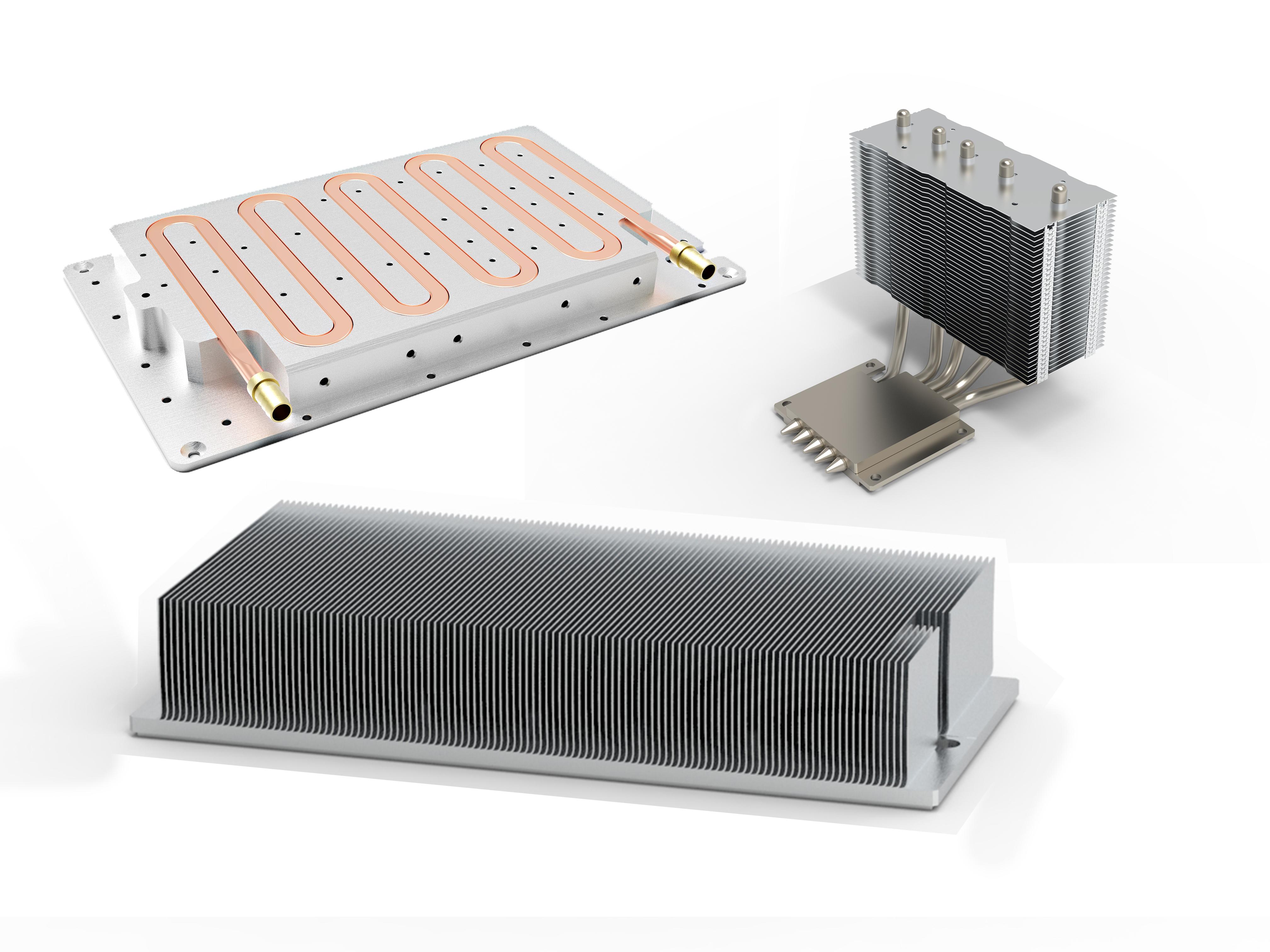

Introducing the Solution: This is where the custom heat sink becomes indispensable—a precisely engineered component tailored to an application's unique thermal profile, footprint, and environment.

-

Thesis Statement: This guide delves into every aspect of custom heat sink design and manufacturing, providing a roadmap for engineers to achieve optimal thermal performance and reliability.

-

II. Why Go Custom? The Limitations of Standard Heat Sinks

-

Space & Footprint Constraints: Standard parts rarely fit perfectly, leading to wasted space or inadequate cooling.

-

Thermal Mismatch: Off-the-shelf solutions are generalized; they cannot target specific hot spots or match the precise thermal resistance ($R_{th}$) required by the component.

-

Keyword Focus: Custom heat sink design optimization, thermal resistance requirements.

-

-

Airflow & Environmental Factors: Custom designs factor in the exact airflow (natural/forced convection) and ambient conditions (dust, vibration, humidity), which standard parts ignore.

-

Cost Efficiency in Volume: For high-volume production, a fully custom heat sink can often be more cost-effective than modifying or over-specifying a standard part.

-

Aesthetic & Mechanical Integration: Custom solutions ensure seamless mechanical integration and can meet specific aesthetic needs.

III. The Foundation of Custom Heat Sink Design: Key Thermal Parameters

This section is vital for establishing technical authority. Use bullet points and maybe a simple table.

-

Heat Load ($Q$ in Watts): The total power dissipated by the source component (TDP). This is the starting point for any custom heat sink project.

-

Maximum Junction Temperature ($T_{j,max}$): The maximum allowable temperature for the semiconductor junction, a non-negotiable limit for device longevity.

-

Ambient Temperature ($T_{a}$): The temperature of the cooling medium (air or liquid).

-

Thermal Resistance ($R_{th}$): The key metric.

-

Formula: $R_{th} = (T_{j,max} - T_{a}) / Q$.

-

A custom heat sink is specifically designed to achieve a target $R_{th}$ that is often much lower than what standard parts can offer.

-

-

Thermal Interface Materials (TIMs): A critical link. Discuss various TIMs (grease, pads, phase change materials) and their impact on overall $R_{th}$ in a custom thermal solution.

| Material Type | Thermal Conductivity (W/m·K) | Best Use Case |

| Aluminum (Al 6061/6063) | $\approx 160-200$ | Cost-effective, Extrusion |

| Copper (C110) | $\approx 380-400$ | High-performance, Small footprint |

| Heat Pipes (Copper/Water) | Up to $10,000$ | Spreading heat over a large base |

IV. Advanced Custom Heat Sink Fabrication Techniques

A deep dive into manufacturing processes, correlating each with specific design benefits and cost implications.

-

1. Extruded Custom Heat Sinks (Most Common):

-

Process: Pushing heated aluminum through a die.

-

Pros: Low cost, good performance, ideal for high volumes and simpler fin geometries.

-

Keyword Focus: Aluminum extrusion heat sinks, extruded custom heat sink profiles.

-

-

2. Forged Heat Sinks (MicroForging®):

-

Process: Stamping material under high pressure.

-

Pros: High-density, high-aspect ratio fins (taller and thinner), excellent for forced convection.

-

Cons: Higher tooling cost.

-

-

3. Skived Fin Heat Sinks:

-

Process: Cutting and bending fins from a single block of material (often copper).

-

Pros: Excellent thermal conductivity (no joint resistance), very fine fin pitch.

-

Cons: Limited height/size.

-

-

4. Brazed/Bonded Fin Heat Sinks:

-

Process: Bonding discrete fins (often copper) to a separate base plate.

-

Pros: Allows for very tall fins and mixed materials (e.g., copper base, aluminum fins).

-

Keyword Focus: Bonded fin heat sink manufacturers, high-performance heat sink solutions.

-

-

5. Machined Heat Sinks (CNC):

-

Process: Precision cutting from a solid block.

-

Pros: Perfect for complex, low-volume prototypes or extremely complex geometries.

-

Cons: High material waste, high cost.

-

V. Design Considerations for High-Performance Custom Heat Sinks

-

Fin Geometry & Optimization:

-

Straight Fins: Best for unidirectional airflow.

-

Pin Fins: Best for omni-directional airflow or heat sources with a small footprint.

-

Staggering & Slotting: Techniques to intentionally disrupt the boundary layer and increase the convection coefficient.

-

-

Heat Spreaders & Heat Pipes:

-

When the heat source is small and very hot (high heat flux), a base-integrated heat spreader (often copper) or embedded heat pipes are essential for efficiently moving heat across the heat sink base.

-

-

Material Selection: Deep-dive comparison (Al vs. Cu).

-

Aluminum is standard for mass/cost.

-

Copper is necessary for high heat flux areas due to its superior conductivity.

-

Hybrid designs (Copper slug embedded in an Aluminum base) offer a blend of performance and low weight.

-

-

Airflow vs. Pressure Drop: A key design trade-off. Tighter fin spacing improves surface area but increases air pressure drop, potentially requiring a more powerful (and louder/costlier) fan. Custom heat sink design balances this equation perfectly.

-

Surface Finish: Discuss the role of anodization (electrically insulating) and other coatings in optimizing radiation and preventing corrosion.

VI. The Custom Heat Sink Development Process: From CFD to Production

A step-by-step guide for potential clients.

-

Step 1: Requirements Definition: Defining $T_{j,max}$, $T_{a}$, Power ($Q$), spatial constraints, and mounting method.

-

Step 2: Computational Fluid Dynamics (CFD) Modeling:

-

The cornerstone of custom heat sink development. Simulating thermal performance and airflow before cutting metal.

-

Allows for rapid iterative optimization of fin count, height, and pitch.

-

-

Step 3: Prototyping & Testing: Creating a low-volume sample (often CNC machined) for real-world thermal testing and validation.

-

Step 4: Tooling & Mass Production: Moving to the final chosen manufacturing method (extrusion, forging, etc.) and implementing Quality Control (QC) checks.

VII. Real-World Applications of Custom Heat Sink Solutions (Approx. 200 words)

Provide concrete examples to illustrate the need for customization.

-

Telecommunications: 5G base stations with high-power RF amplifiers require extremely dense, high-performance, weather-resistant custom heat sinks.

-

Automotive: Electric vehicle battery management systems and power electronics (inverters/converters) demand rugged, vibration-proof, and often liquid-cooled custom solutions.

-

Data Centers & AI: Server CPUs and GPUs with ever-increasing TDPs need specialized two-phase (heat pipe/vapor chamber) custom heat sink assemblies.

-

Industrial Power: High-power LED lighting, motor controllers, and welding equipment.

VIII. Conclusion: Partnering for Thermal Success

-

Recap: Reiterate that in today's high-density electronics landscape, generic cooling is a recipe for failure. The custom heat sink is not a luxury, but a necessity for maximizing performance and longevity.

-

Final Call to Action (CTA): Emphasize the value of partnering with an experienced custom heat sink manufacturer that offers end-to-end services (CFD, prototyping, and various manufacturing options).

-

Closing Thought: Don't let thermal runaway be the Achilles' heel of your innovation. Invest in a precise, bespoke thermal solution.