Manufacturing data analytics is reshaping production environments by enabling data-driven decisions at every level. According to McKinsey, data-driven manufacturing can lead to productivity gains of up to 30%. Another report by PwC reveals that nearly 70% of manufacturers are either adopting or planning to adopt augmented reality (AR) technologies in the next two years. The convergence of AR and manufacturing data analytics is not just a technological trend but a foundational shift.

This article explores the technical integration of augmented reality within manufacturing analytics, highlighting its capabilities, challenges, and real-world implementations.

What Is Augmented Reality in Manufacturing?

Augmented reality refers to the digital overlay of information—text, graphics, or data—onto a user’s physical environment through devices like smart glasses, tablets, or headsets. In manufacturing, AR helps operators visualize complex data without disrupting workflows.

When paired with manufacturing data analytics, AR enables:

-

Real-time display of key metrics on machines or components

-

Hands-free guidance during maintenance and assembly

-

Visualization of predictive analytics for equipment failure

Technical Foundation: How AR Integrates with Manufacturing Analytics

AR systems in manufacturing rely on several core technologies:

-

IoT Sensors: These collect data from machines and send it to central systems.

-

Edge Computing: Processes data close to the source for real-time performance.

-

Analytics Platforms: Analyze data and generate visual outputs.

-

AR Devices: Display insights to operators directly in their line of sight.

This system forms a closed loop. Data is gathered, analyzed, and immediately rendered into actionable visual formats for shop floor personnel.

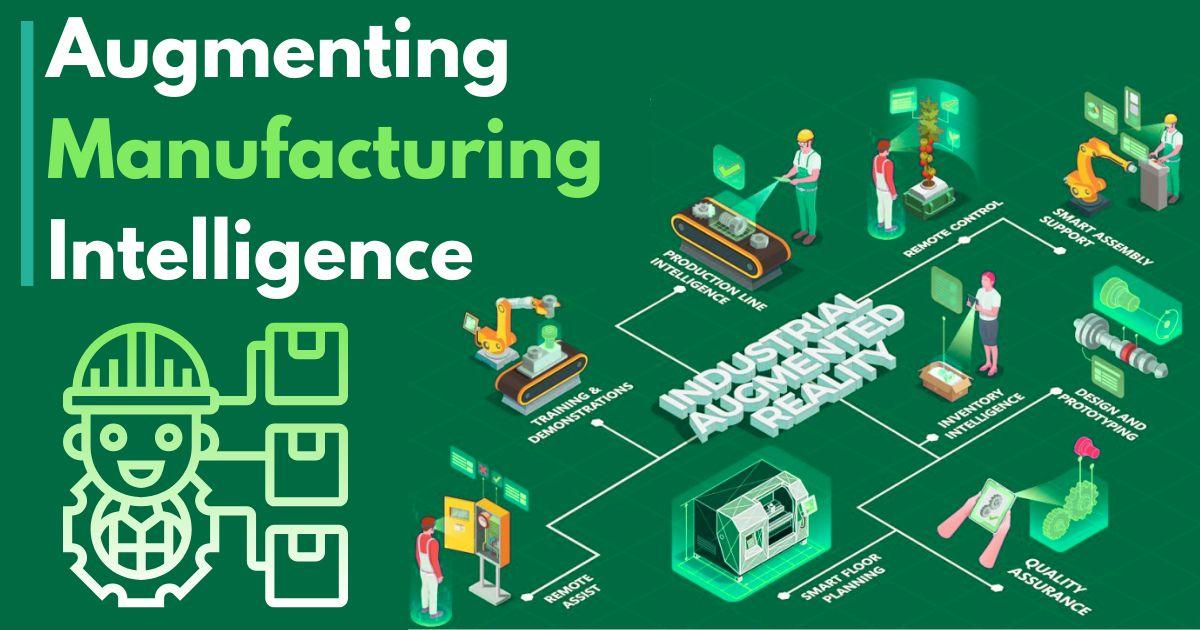

Applications of AR in Manufacturing Data Analytics

1. Predictive Maintenance

By visualizing predictions on equipment health, AR supports preventive actions:

-

Operators can see wear data overlaid on machinery.

-

Alerts and remaining useful life can appear in real-time.

Example: Boeing uses AR headsets that show real-time component diagnostics, reducing troubleshooting time by 25%.

2. Quality Inspection and Assurance

AR enhances inspection by offering visual comparisons and data overlays:

-

Inspectors compare real-time production with ideal parameters.

-

Anomalies are highlighted automatically.

Example: Porsche integrates AR with analytics to guide staff during visual inspections. Fault detection accuracy improved by 18%.

3. Training and Skill Transfer

New operators can learn from real-time, data-driven instructions:

-

Virtual guidance shows step-by-step procedures.

-

Historical analytics guide decision-making in ambiguous cases.

Example: GE Aviation uses AR for training jet engine technicians. Training duration decreased by 35%.

4. Assembly Line Optimization

AR supports assembly by displaying contextual analytics:

-

Operators can view KPIs related to output, efficiency, or error rates.

-

Changes in process data update AR visuals instantly.

Table 1: AR Use Cases and Impact

| Application | Benefit | Reported Impact |

| Predictive Maintenance | Reduced downtime | 20–30% less downtime |

| Quality Assurance | Better defect detection | 15–25% improved detection |

| Training | Faster onboarding | 30–40% reduced training time |

| Assembly | Increased productivity and safety | 10–15% more efficient lines |

Data Visualization with AR

AR devices convert raw data from manufacturing analytics platforms into intuitive visuals. These can include:

-

Heatmaps showing machine stress levels

-

Graphs of historical performance next to equipment

-

Color-coded warnings for thresholds

Operators receive contextual insights without needing to interpret raw reports or dashboards.

Security and Data Integrity Considerations

While AR increases accessibility, it also introduces challenges:

-

Authentication: Ensuring secure device access.

-

Data Integrity: Preventing manipulation of analytics.

-

Latency: Real-time demands need robust networks.

Cybersecurity protocols must extend to edge devices and AR endpoints to ensure consistent and safe operations.

Real-World Examples

-

Siemens deployed AR analytics to visualize equipment KPIs across plants, improving cross-site coordination.

-

Lockheed Martin uses AR with manufacturing data analytics for spacecraft assembly. Accuracy improved, and build times decreased.

-

Ford Motor Company applies AR-guided data analytics to streamline vehicle diagnostics on the assembly line.

Challenges to Adoption

Manufacturers face barriers when integrating AR into data workflows:

-

High upfront costs of AR devices

-

Resistance to new tools from experienced operators

-

Need for robust data infrastructure

Mitigation involves phased implementation, operator training, and cloud-AR integration planning.

Future Outlook

The integration of AR with manufacturing analytics is expected to deepen in the next decade. With 5G networks, real-time analytics visualizations will become faster and more reliable. Moreover, AI integration will enhance AR systems to proactively recommend actions based on live data.

Conclusion

Augmented reality is transforming how insights from manufacturing data analytics are consumed and applied on the factory floor. Its ability to deliver real-time, contextualized, and actionable insights empowers teams to act faster and more accurately. As adoption expands, AR will become a critical interface between data systems and human operators.

For manufacturers seeking to enhance decision-making and operational visibility, AR represents not just a visual tool, but a pivotal component in next-generation manufacturing intelligence.

Frequently Asked Questions (FAQs)

1. How does augmented reality (AR) enhance manufacturing data analytics?

Answer:

AR acts as a visual interface that translates complex manufacturing data analytics into intuitive, real-time visuals for shop floor operators. Instead of reading reports or accessing dashboards from a computer terminal, workers can see key performance indicators (KPIs), predictive maintenance alerts, and quality control data directly in their line of sight through smart glasses or tablets. This leads to faster decision-making, reduced downtime, and improved productivity.

2. What types of data are typically visualized through AR devices in manufacturing?

AR devices can visualize a wide range of manufacturing data, including:

-

Machine performance metrics (e.g., RPM, temperature, pressure)

-

Predictive maintenance alerts (e.g., component wear, failure forecasts)

-

Quality assurance checkpoints (e.g., tolerances, inspection targets)

-

Assembly instructions with real-time analytics (e.g., torque values, assembly time)

-

Safety warnings and compliance data (e.g., thresholds for hazardous conditions)

These visuals are layered contextually over physical equipment or products, enabling hands-free, data-driven action.

3. What are the key challenges in implementing AR with analytics in a manufacturing environment?

Key challenges include:

-

Cost of hardware: AR headsets and infrastructure can be expensive for large-scale deployment.

-

Data integration complexity: Connecting AR systems with existing IoT sensors, MES, ERP, and analytics platforms requires robust integration planning.

-

Workforce resistance: Some workers may be hesitant to adopt new technology due to lack of training or familiarity.

-

Network requirements: AR with real-time data visualization needs high-speed, low-latency networks like 5G or industrial Wi-Fi.

-

Security concerns: AR systems must ensure data integrity and secure access to sensitive analytics data.

4. Which industries are leading in the adoption of AR-driven analytics in manufacturing?

Industries with complex assembly processes and strict quality requirements are leading adopters of AR-driven analytics. These include:

-

Aerospace – for real-time visualization during spacecraft and aircraft assembly (e.g., Lockheed Martin)

-

Automotive – for diagnostics, quality inspections, and production optimization (e.g., Ford, Porsche)

-

Electronics – for PCB assembly and defect detection

-

Pharmaceuticals – for compliance visualization and guided training

-

Heavy Machinery – for predictive maintenance and field service guidance

These sectors benefit from AR’s ability to reduce human error and provide real-time insights in dynamic manufacturing environments.

5. What is the future outlook for AR in manufacturing analytics?

The future of AR in manufacturing analytics is promising. Advancements in 5G, AI, and edge computing will make real-time data streaming and visualization faster and more accessible. AR will become more lightweight and integrated with wearable devices, allowing for greater mobility. Additionally, the fusion of AR with generative AI will enable predictive recommendations, intelligent visual cues, and automated decision support directly in the worker’s field of view. As more manufacturers adopt digital twins and Industry 4.0 frameworks, AR will evolve from a productivity enhancer to a standard interface in data-driven smart factories.