In today’s competitive manufacturing landscape, efficiency and precision are crucial to staying ahead. One innovation that has transformed the manufacturing process is the automated riveting machine. These machines, designed to automate the rivet insertion process, offer manufacturers a way to streamline production, reduce errors, and improve overall quality. Expert Technologies Group, known for providing advanced industrial solutions, is at the forefront of offering state-of-the-art automated riveting machines to industries worldwide.

What Is an Automated Riveting Machine?

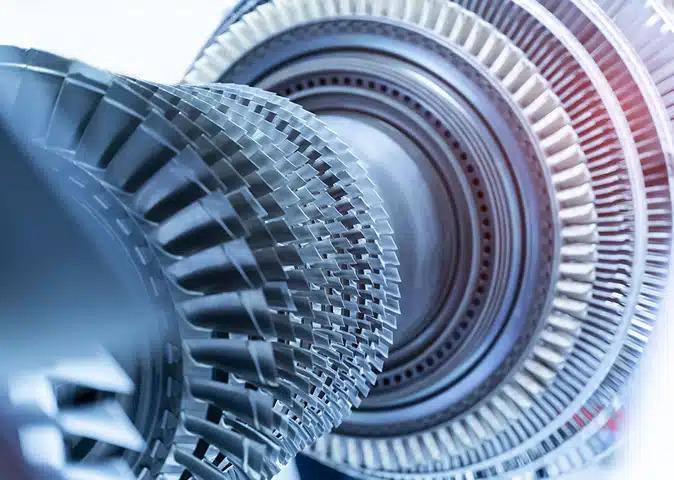

An automated riveting machine is an industrial tool designed to automate the process of fastening rivets to join materials together. Rivets are commonly used in various industries to secure materials, particularly metals, and are a more permanent and secure fastening solution than traditional screws or bolts. In an automated system, the process of inserting rivets and securing materials is handled by machines, which are equipped with sophisticated controls to ensure precision, speed, and consistency.

Unlike manual riveting, which requires workers to insert and set each rivet by hand, an automated riveting machine handles all aspects of the process, from positioning the material to setting the rivet. This leads to faster production times, increased consistency, and fewer defects in the finished product.

How Automated Riveting Machines Work

The operation of an automated riveting machine can be broken down into a series of controlled steps, each contributing to the precision and efficiency of the process:

-

Material Loading: The materials to be joined are loaded into the machine. The system aligns the materials automatically, ensuring they are correctly positioned for the riveting process.

-

Rivet Insertion: The machine’s automated feeding system ensures that rivets are correctly placed into the desired position. This can be done using robotic arms or automated feeders that accurately deliver rivets to the appropriate location.

-

Setting the Rivet: The riveting head of the machine applies pressure to the rivet, causing it to expand and securely fasten the materials together. The machine controls the force applied to ensure the rivet is correctly set for a strong, durable connection.

-

Quality Assurance: Many automated riveting machines come with built-in sensors that monitor each step of the riveting process. These sensors ensure that rivets are applied accurately and securely, reducing the risk of defects or weak joints.

By automating this critical step in the production process, manufacturers can achieve higher output, better quality control, and reduced labour costs.

Key Advantages of Automated Riveting Machines

1. Increased Productivity

One of the most significant advantages of automated riveting machines is the speed with which they can complete the riveting process. Unlike manual methods, where each rivet must be inserted and set by hand, automated machines can perform this task much faster. This leads to greater overall production capacity, allowing manufacturers to meet higher demand while maintaining product quality.

2. Precision and Consistency

Automated riveting machines excel in delivering consistent results. Since the process is controlled by precise programming, there is little room for human error. Every rivet is placed with the same amount of force and accuracy, ensuring uniform results. This consistency is critical for industries where even the smallest variation in rivet placement can impact the integrity and quality of the final product.

3. Reduced Labour Costs

Automating the riveting process reduces the need for manual labour, which can be both time-consuming and costly. With an automated riveting machine in place, businesses can minimise their reliance on workers for this repetitive and physically demanding task. This not only reduces wages but also improves the overall efficiency of the production line.

4. Minimising Defects

Manual riveting can lead to defects such as misaligned rivets, improperly set rivets, or inconsistent pressure. Automated systems eliminate these risks, significantly reducing the likelihood of defects in the finished product. The machine’s precision ensures that every rivet is installed correctly, enhancing the durability and safety of the final product.

5. Improved Workplace Safety

Riveting can be a physically demanding task, especially in high-volume production environments. Manual riveters are often required to apply significant force when inserting and setting rivets, which can lead to fatigue or injury over time. Automated riveting machines take over this physically strenuous task, improving worker safety and reducing the likelihood of workplace injuries related to repetitive strain.

6. Flexibility for Different Applications

Automated riveting machines can be configured to handle a wide range of rivet sizes, materials, and joint configurations. This flexibility makes them suitable for use in diverse industries such as aerospace, automotive, electronics, and construction. Whether you're assembling lightweight components or heavy-duty structures, automated riveting machines can be adapted to meet your needs.

Industries Benefiting from Automated Riveting Machines

Automated riveting machines are employed across various sectors, where their speed, precision, and cost-saving capabilities make them invaluable. Some industries benefiting from these machines include:

1. Aerospace

In the aerospace industry, the quality and integrity of every component are critical to ensuring the safety and reliability of aircraft. Automated riveting machines are used to assemble various parts of aircraft, such as fuselages, wings, and landing gears. The machines provide the high precision needed to ensure that rivets are properly set, helping to meet the stringent safety standards of the aerospace sector.

2. Automotive

Automotive manufacturers use automated riveting machines to join metal body parts and frame structures. The machines help increase production speed while maintaining consistent quality, allowing manufacturers to meet the high demand for vehicles in a competitive market.

3. Electronics

In the electronics industry, automated riveting machines are used to assemble components such as enclosures, casings, and other small parts. The precision of these machines ensures that rivets are securely placed without damaging delicate electronic components.

4. Construction

In the construction sector, automated riveting machines are employed to assemble large metal structures, such as bridges, buildings, and industrial equipment. These machines improve the efficiency of the construction process, ensuring that components are securely fastened and that the finished structure meets safety and quality standards.

Expert Technologies Group: Your Partner in Automation

Expert Technologies Group is a leader in providing innovative automation solutions, including automated riveting machines. With years of experience in the field, the company offers customised solutions designed to improve the efficiency and precision of your production lines. Whether you are in the aerospace, automotive, electronics, or construction sector, Expert Technologies Group has the expertise to provide the right riveting machine for your needs.

Why Choose Expert Technologies Group?

- Innovation: The company is committed to providing cutting-edge technology, ensuring that your business benefits from the latest advancements in automation.

- Tailored Solutions: Expert Technologies Group works closely with clients to understand their specific requirements and provide tailored solutions that optimise production processes.

- Support and Maintenance: The company offers comprehensive support, from initial installation and training to ongoing maintenance, ensuring your machines continue to operate at peak performance.

Conclusion

The automated riveting machine is a vital tool for modern manufacturers, offering increased productivity, precision, and cost savings. With its ability to streamline the riveting process, businesses can achieve faster production times, fewer defects, and better overall product quality.

As industries continue to evolve, adopting automated systems like riveting machines will become increasingly important to maintain competitive advantage. By partnering with Expert Technologies Group, manufacturers can stay ahead of the curve, ensuring their operations remain efficient, safe, and cost-effective.